LM555 Timer Circuits and Understanding

LM555 Timer Circuits and Understanding

This page presents general information and tips for using the LM555 timer and devices with other letter prefixes. There will be minor internal circuitry differences between 555 timer IC's from the various manufacturers but they all should be useable for the circuits on this page.

If you would like to use any of these ideas, take the time to do some testing before using the LM555 timer in an actual circuit.

Learn how to build a simple 220AC inverter using a 555timer

CMOS Versions Of The 555 Timer

All of the information on this page can be applied to the low current, CMOS versions of the 555 timer as well.

However, the CMOS versions have a lower output current rating and may not be able to drive some loads. Also, the outputs of some CMOS timers can source more current than they can sink.

For single sided loads, an NPN or PNP driver transistor can be added to the output of the timer to increase the current capacity of the timer. ( See section 31 of this page for more information. )

LM555 Timer Internal Circuit Block Diagram

LM555 Timer Internal Circuit Block Diagram

Print the diagram in the centre of a sheet of paper and then draw a circuit using the ICs pin locations.

Example LM555 circuit.

LM556 Timer Internal Circuit Block Diagram

Print the diagram in the centre of a sheet of paper and then draw a circuit using the ICs pin locations.

Most of the circuits at this web site that use the LM555 and LM556 timer chips do not show connections for the RESET and CONTROL inputs. This was done in order to keep the schematics as simple as possible.

If the RESET terminal of a 555 or 556 timer is not going to be used, it is normal practice to connect this input to the supply voltage. If the RESET terminal is left unconnected the operation of the timer will not be affected, however, the RESET of CMOS version of these timers should not be left unconnected as the inputs of these devices are more sensitive and this may cause problems.

In many cases the CONTROL input does not require a bypass capacitor if a well regulated power supply is used. However, it is good practice to place a 0.1 microfarad (C2) capacitor at this terminal to minimize voltage spikes during transitions of the timer's output transistors.

It is also good practice to place a 0.1uF bypass capacitor (C1) across the power supply and located as close to the IC as possible. This will also reduce voltage spikes when the output transistors of the timer change states.

Typical Pin 4 And 5 Connections

Note - If the period of the power supply variations is short when compared to the period of the timer, the overall effect of C2 is reduced.

For example; If the power supply - ripple voltage is 120 Hz and the oscillator frequency is 1000 Hz then C2 will have greater benefit than if the oscillator frequency is 10 Hz.

Therefore, at low astable frequencies or long monostable times the effectiveness of a capacitor at the CONTROL input is less than at higher frequencies and short pulse times.

LM555 Monostable Oscillator Circuit Diagram

LM555 Monostable Oscillator Output Time Chart

RESET And CONTROL Input Terminal Notes LM555 Astable Oscillator Circuit Diagram

LM555 Astable Oscillator - Free Running Frequency Chart

Basic Circuits For The LM555 Timer

The following diagrams show some basic circuits and calculations for the LM555 timer.

Circuit 1

Circuit 5 also has a trigger input that can remain closed and still allow the timer to complete its cycle. This means that the trigger input pulse can be longer than the output pulse.

Triggering And Timing Helpers For Monostable Timers

The LM555 timer and its twin brothers the LM556 are cornerstones of model railroad electronics but the sensitivity of the trigger input gives rise to many false triggering problems. The addition of a 470K ohm resistor and a 0.1uF capacitor at the TRIGGER input (Pin 2) will provide a delay of approximately 1/20th of a second from the time the input goes to zero volts until the trigger threshold of 1/3Vcc is reached. This short delay can eliminate false triggering in most cases and if the problem persists the value of the capacitor or resistor can be increased as needed.

The following schematic shows two additions to the basic 555 timer circuit. One reduces the trigger sensitivity and the other will double the output pulse duration without increasing the values of R1 and C1.

555 Timer Helpers Schematic

The addition of a resistor and capacitor to the trigger will not work for very short output pulses as there is also an RC delay in the recovery of the trigger terminal voltage.

The value of the 0.1uF capacitor at the trigger terminal can be made larger to further delay the triggering of the timer when the input goes LOW. Other values can be used in place of the 470K resistor as well.

The second addition is a helper that will extend the timers output duration without having to use large values of R1 and/or C1. Connecting a 1.8K ohm resistor between the supply voltage and pin 5 of the 555 timer chip the output pulse duration will be approximately doubled.

The boxed in area of the drawing shows the internal circuit at pin 5 of the timer with the 1.8K resistor added. The voltage at pin 5 will be increased from 0.66Vcc to 0.88Vcc which is approximately equal to the voltage across the capacitor after two time constants*. This allows the same output time to be achieved with a smaller resistance or capacitance value thus reducing the error caused by the capacitor leakage current. Conversely, for a given value of R1 and C1, the output time will be doubled by the addition of the resistor at Pin 5.

* - One time constant is equal to R (Ohms) times C (Farads) in seconds. In terms of voltage, one time constant is equal to a rise in voltage across the capacitor from 0 to 63.2 percent its maximum voltage. (1uF = 0.000,001F = 1 X 10-6F)

The trigger and reset voltage levels of the timer will also be increased with the addition of the resistor to pin 5 but this should have no effect in most applications.

To achieve long output times, electrolytic capacitors are often used for C1 and the value of R1 can be as high as 1 Megohm. However with high resistance values for R1 the leakage current of the timing capacitor (C1) becomes a significant factor in the operation of the timer.

The circuit will run much longer than expected and may never time out if the leakage current is equal to the current through the resistor at some voltage. Tantalum capacitors could be used as they have very low leakage currents but these are expensive and not available in large capacitance values.

Adding a resistor to the CONTROL terminal is not an ideal solution to solving long duration timing situations but should work for pulse times of less than ten minutes.

Reversed Trigger Input Control Of 555 Timers

The following method allows the timer to be triggered by a normally closed switch. This would be useful in applications such as intrusion alarms where the protection circuit is broken if a window or door is opened

Reversed Trigger Input

Controlling Circuits For LM555 Timers

The following diagrams show some methods of using one-shot timer to control an astable oscillator.

LM555 Control methods #1 schematic

Advanced Circuits For The LM555 Timer

The following diagrams show some advanced circuits for the LM555 timer. These circuits were developed to provide certain functions that are not typically associated with this device.

The parts values in these circuits were selected for testing purposes and can be adjusted to suit the needs of a particular application as long as the normal operating parameters of the LM555 are maintained.

Before using any of these circuits for specific applications they should be tested to determine the best values for the components and the practicality of their use.

LM556 Timers with Complimentary or Push-Pull Outputs

In the next circuit an LM556 - dual timer IC is configured so that the output of the second timer is 180 degrees out of phase with the first.

This is done by connecting the OUTPUT of timer A to the TRIGGER and THRESHOLD terminals of timer B. The 10K ohm resistor limits the current that can flow into the THRESHOLD terminal of timer B.

Due to the ability of the timers to source or sink current, the current from one timers output can flow into the other timer's output depending on which output is HIGH or LOW. The typical output conditions that are referenced to ground or supply are also available and in fact all three could be used at the same time.

Circuits for both Astable and Monostable versions of this method are shown on the diagram.

LM555 Complimentary Outputs schematic

Timer B in this method acts as a voltage comparator and has no timing function. It is a slave to timer A.

Normal triggering methods and period lengths are not affected.

Both timer's RESET terminals are available and can be used individually or together.

Due to the unusual nature of this type of circuit testing should be done to determine if it is suitable for the use intended. The circuit is usable at frequencies below 1000 Hz.

Interlocked Monostable Timers

In the following circuit the timers are interlocked so that while one timer is running the second timer cannot be triggered.

This is done by connecting the OUTPUT of each timer to the TRIGGER of the other through a diode and placing a resistor in the trigger circuit. The resistor limits the current from the opposite timers output when the trigger is closed on the stopped timer.

LM555 Interlocked Timers schematic

Normal triggering and timing lengths are not affected by this method.

Power-Up Reset For 555 Timers

Monostable 555 timer circuits will automatically trigger and start a timing cycle when power is applied to the circuit. The timer's internal circuitry is largely responsible for this triggering but it is also caused stray or installed capacitance at the TRIGGER terminal of the timer.

Triggering at power-up can be a undesirable if the period is long and there is no way to stop the cycle once it has begun.

The stray capacitance can be from a number of sources but a typical source is the wires that connect a push button used to trigger the timer.

To prevent timer from starting, a simple RC and transistor circuit can be connected to the timer's RESET terminal so that when power is applied to the circuit, the timer is automatically held RESET by transistor Q1 until C1 is almost fully charged.

The length of the resetting action can roughly be determined by R1 X C1 X 3 .

The example circuit shows a monostable oscillator but the method could also temporarily hold an astable 555 oscillator in a reset condition at power-up.

LM555 Power-Up Reset Method 1

The following circuit is another method of stopping the timing cycle at power-up. In this case, a pulse is sent to the THRESHOLD terminal which stops the timing cycle when the power is applied.

LM555 Power-Up Reset Method 2

Cross Canceling For Monostable Timers

The following diagram shows a method that allows one LM555 timer to RESET another timer so that, for example, if timer 'A' is running; When timer B is triggered, timer A will be reset.

This means that only one timer can be running at a time.

As with the 'Power-Up Reset For Monostable Timers' circuit above, when the power is applied to the circuit both timers are RESET.

LM555 Cross Canceling Timers schematic

Normal triggering and timing lengths should not be affected by this method.

The trigger switch of the running timer must be OPEN for the RESET to occur.

Reset/Set Flip-Flop Made With A LM556 Timer

The next circuit is for a hybrid - SET / RESET type of logic Flip-Flop that is constructed from an LM556 - Dual Timer.

The design is crude but effective for very low speed applications. Its greatest asset is that the outputs of the LM556 are capable of driving current loads of up to 200 milliamps with a minimal voltage loss.

This circuit was originally developed to drive "Stall Motor" type switch machines that are used on model railroads. These motors operate on 12 volts, or less, and draw approximately 15 milliamps when they are stalled.

Due to the design of the LM556 timer chip there are multiple output options available in this circuit. These include the normal timer outputs which are bipolar and the DISCHARGE terminals, (PINS 1 and 13), that are open collector circuits.

LM556 Flip-Flop Truth Table

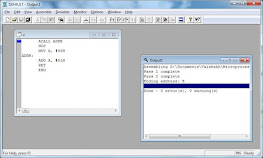

The following diagram is for a test version of the LM556 Flip-Flop circuit used to create a "Truth Table" that shows the OUTPUT states for a given INPUT state.

Logic Function diagram

Because there are two inputs for each half of the 556 timer, the input voltages must go above and below the TRIGGER voltage and above the THRESHOLD levels for the circuit to operate correctly. Therefore the ratios of R1/R3 and R2/R4 is important but their actual values are not.

Also, the impeadance of the inputs must be low enough to allow for these voltage levels to be achieved.

The next diagram has the TRIGGER and THRESHOLD terminals of the timers separated. The basic function is the same as the circuit above but the output can only change when the input treminals are made low.

Separated Trigger And Threshold Terminals

LM556 Flip-Flop Input Options

The next diagram shows basic input options that can be used with the LM556 Flip-Flop circuit. In actual applications the push buttons could be replaced with or supplemented by electronic input devices.

Input Options schematic

In circuit A the SET and RESET inputs is brought to 0 Volts to change the state of the Flip-Flop.

In circuit B the SET input is switched between 0 Volts and Vcc, the supply voltage, to change the state of the Flip-Flop. The RESET terminal is unconnected.

In both circuit A and B, when the push buttons are OPEN the Flip-Flop will remain in its last state until the opposite signal is applied to an input.

Circuits A and B also show two methods of connecting the LED's at terminals 1 and 13. The input method in circuit B would not be practical to produce the STATE 3 condition shown in the Truth Table on the previous diagram.

LM556 Flip-Flop Notes

- If you would like to make use of this type of circuit, please take the time to build one and do some experimenting to determine if the design will suit your needs.

- This circuit was developed for low speed operation. It was found however to operate satisfactorily at clock speeds in excess of 10 kHz.

The values of R1 and R2 in this test were 100K ohms. The value of R3 was 22K ohm.

- As can be seen in the schematics, the OUTPUT of one timer is fed, through a 10K ohm current limiting resistor (R1 and R2), to the TRIGGER and THRESHOLD inputs of the other. The value of this resistor is not critical and is largely dependent on the impedance of the INPUT devices used to trigger the stage changes.

If resistors R1 and R2 are not used the operation of the circuit becomes unstable.

- Due to the internal circuitry at THRESHOLD terminals (PINs 6 and 12) of the LM556 timers, resistors R3 and R4 are needed to limit the current that can flow into these terminals. The value of resistors R3 and R4 should be approximately 1/4 the value of resistors R1 and R2 so that the proper voltage ratios for changing states can be achieved.

The R3 resistor is not required if the inputs are not going to be driven to a HIGH state.

- The cross coupling of the timers OUTPUT and TRIGGER/THRESHOLD terminals gives the circuit its FLIP-FLOP action and causes the outputs of the timers to be forced alternately HIGH or LOW. This action only applies to states 1 and 2 in the truth table shown above.

- For this circuit to have a memory function such as that of a SET / RESET type Flip-Flop the input terminals must float when no input signal is present. They cannot be held HIGH or LOW as is the case with TTL devices.

- The maximum current the the outputs of the LM556 timers can source or sink is 200 milliamps.

- These circuits do not need a regulated power supply but the voltage should be well filtered.

- Any of the LED's in the circuit could be replaced by an optoisolator, small relay or low current DC motor.

LM555 Timer Used As A Voltage Comparator Or Schmitt Trigger

The next section shows how an LM555 timer can be used as a voltage comparator or a Scmitt Trigger with a large offset voltage. The 555 timer is not well suited for this application but it is one that is in wide use with model railroaders.

Shown on the schematic is a secondary output that uses the open collector at the DISCHARGE terminal (Pin 7) of the timer. This output can sink up to 200 milliamps and would be ideal for driving relays.

The main disadvantage to using this circuit is the the large dead-band (1/3Vcc) between upper and lower threshold voltages. An optional resistor, R5, can be added to the circuit to lower and compress the detection voltage range but this only partially alleviates the problem.

LM555 Voltage Comparator / Schmitt Trigger

The two graphs at the bottom of the diagram show the input voltages at which the OUTPUT of the LM555 will change states. The effect that resistor R5 has on the circuit can be seen in the right hand graph.

50% Output Duty Cycle (Variable)

The LM555 timer can achieve a 50 percent duty cycle as shown in the next diagram. The duty cycle adjustment range of the give components values is from 42 to 55 percent.

Resistors R1 and R2 were selected first and then resistor R3 was selected to give the best control range based on measurements at the output of the timer.

The major disadvantage of using the LM555 in this manner is that the output frequency changes as the duty cycle changes.

50% Duty Cycle schematic

For The Record

The circuit shown in the next diagram is not an accurate method of producing a 50 percent duty cycle using 555 timers, either bipolar or CMOS types. The circuit can produce a duty cycle that is close to 50 percent but when a load is added to the output of the timer, the voltage drops across its output transistors will increase and the duty cycle will shift.

Not Accurate 50% Duty Cycle schematic

Bipolar LED Driver

This circuit uses two timers to drive Bipolar LEDs and shows all of the possible output states.

Two SPDT switches are used to set the input conditions but these could be replaced by electronic controls.

Bipolar LED Driver schematic

Electronic Time Constant Control

These circuits show methods of changing the operating frequency of astable LM555 timers electronically. Any source that can drive the base of transistor Q1 can control these circuits.

The advantage of switch the timing capacitors is that the duty cycle of the timer is not affected when the frequency is changed.

Electronic Time Constant Control

Voltage Controlled Pulse Width Oscillator

The basic circuit operates at a frequency determined by R1, R2 and C1 and has a pulse width range of 0 to 100 percent.

The following diagram shows a basic circuit with an open collector output that would require a pull up resistor at its output. The parts values are the nominal values of the components used.

Note: This circuit is not suitable for high frequency operation, especially when using a second timer as the output stage.

Variable Pulse Width Oscillator

The following is a graph of the output pulse width of the basic circuit for a given control voltage input. All measurements were made with a good quality multimeter.

The PLUS and MINUS inputs of IC 2 can be reversed to produce a decreasing pulse width for an increasing control voltage.

Variable Pulse Width Oscillator Output Graph

The next diagram uses a second LM555 timer as a power output stage for the basic oscillator. The output stage also has an open collector output at the Discharge terminal, PIN 7, that could be used.

Variable Pulse Width Oscillator With LM555 Output

Sweeping Output Siren

This circuit is a variation of the "Two Tone Siren" that is a standard for the LM555 timer. The circuit allows the output frequency of the B timer to sweep between two frequencies rather than switching abruptly between two frequencies.

Sweeping Output Siren

NOTE: The Sweeping Output Siren circuit has a limited sweep range and the duty cycle shifts with the changing output frequency.

A better 555 based circuit for a sweeping oscillator would be to adapt the Variable Pulse Width Oscillator in the section above.

A still better choice for a sweeping oscillator is a Voltage Controlled Oscillator (VCO) IC. See this Wikipedia page for basic information on Voltage-controlled oscillators and this datasheet for the LM321.